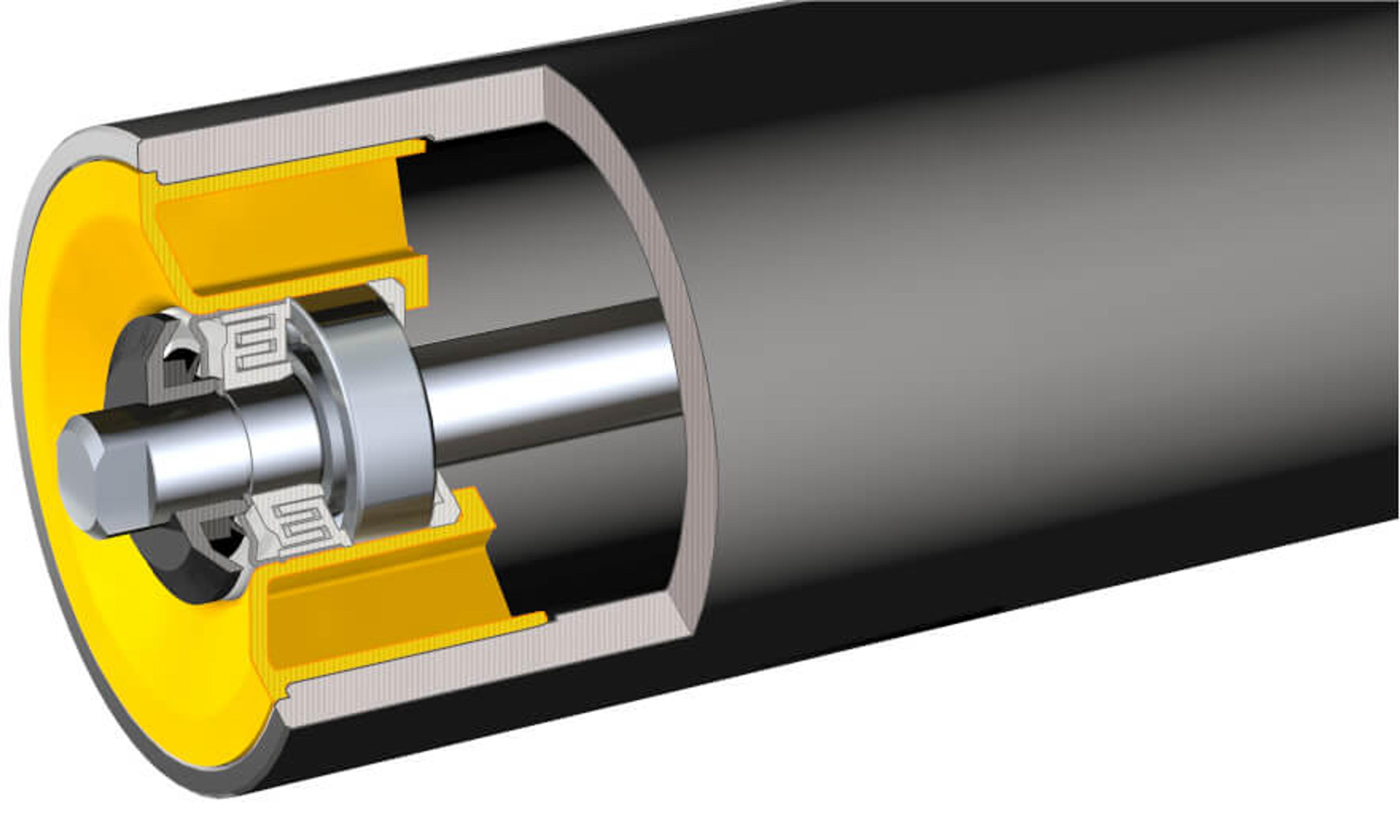

HDPE Roller

The High Density Polyethylene (HDPE) TOB Roller is a light, strong and eco-friendly solution. The TOB Roller helps you maintain a smooth-running plant by offering a number of advantages over a mild steel roller:

Reduced energy cost

The TOB Roller typically weighs up to 40-50% less than steel. This means it requires less energy to start up. This reduction in energy usage makes it more environmentally friendly and profitable to use.

Quick and easy installation

Lengthy production delays to replace rollers can dramatically impact profitability. Because they are lighter, the TOB Roller is physically easier to change out.

Safer technology for reduced risk of injury

Roller failures lead to downtime, a drop in production, and lower profitability. The TOB Roller causes little or no belt damage, and doesn't create jagged steel edges when a roller seizes. This reduces damage to conveyor belt covers, and reduces the risk of injury when the operator has to handle seized items.

Durability

The TOB Roller is more durable than steel, and reduces wear on a belt compared to steel rollers.

Lower noise levels

The noise produced is 10-15% less than with steel rollers, because the thermoplastic absorbs noise.

Reduced spillage

Material doesn't build up on the shell, when compared to a steel roller. This results in reduced tracking issues and spillage of materials.

Features

Available types:

The Roller comes in a variety of sizes, from 89mm to 133 in diameter, 20-25mm shaft, all with 6204 or 6205 bearings.

Load capacity:

The Roller is designed to be an optimal solution for light to medium duty applications.

Sealing:

The Roller comes in both hermetic and contactless styles, which guarantees an excellent performance in the presence of any kind of contaminant.

Material:

The Tube is made of High Density Polyethylene (HDPE), while the bearing housing is made of Homopolymer Acetal Resin.

Applications:

The Roller is excellent for use in a wide variety of applications and products, such as:

- Cement

- Gravel

- Fertilizers

- Ports

- Chemical

- Many other materials

Advantages

The TOB Roller is 50% lighter than a steel roller, which means:

- It consumes less power during starting and stopping the belt conveyor, reducing the power requirements for the plant

- It is easier to mount and maintain, lowering the incidence of back injuries for the operator when mounting or replacing rollers

- Easier and cheaper transportation

The TOB Roller is wear resistant, with a low level of abrasion and corrosion, leading to:

- Longer roller life

- Lower maintenance requirements for the plant

- Less belt wear, since the HDPE tube will not cause belt abrasion

The TOB Roller is highly resistant to chemical agents, which means:

- It will not rust

- It is suitable for a variety of applications

- It has low levels of noise emissions

The TOB Roller has a self-cleaning roller surface, which results in:

- Avoidance of build-up of material, which is the main cause of a belt mis-tracking

- Lower spillage from the belt

The TOB Roller has a low running resistance sealing system, which means:

- Lower motor torque is required for conveyor starts

- The size of the required motor is reduced

- The belt conveyor consumes a reduced level of energy

- Lower belt consumption, due to lower levels of wear

Contact us for a quote.